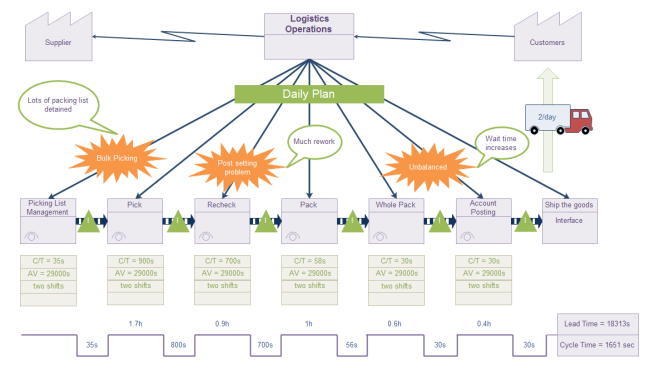

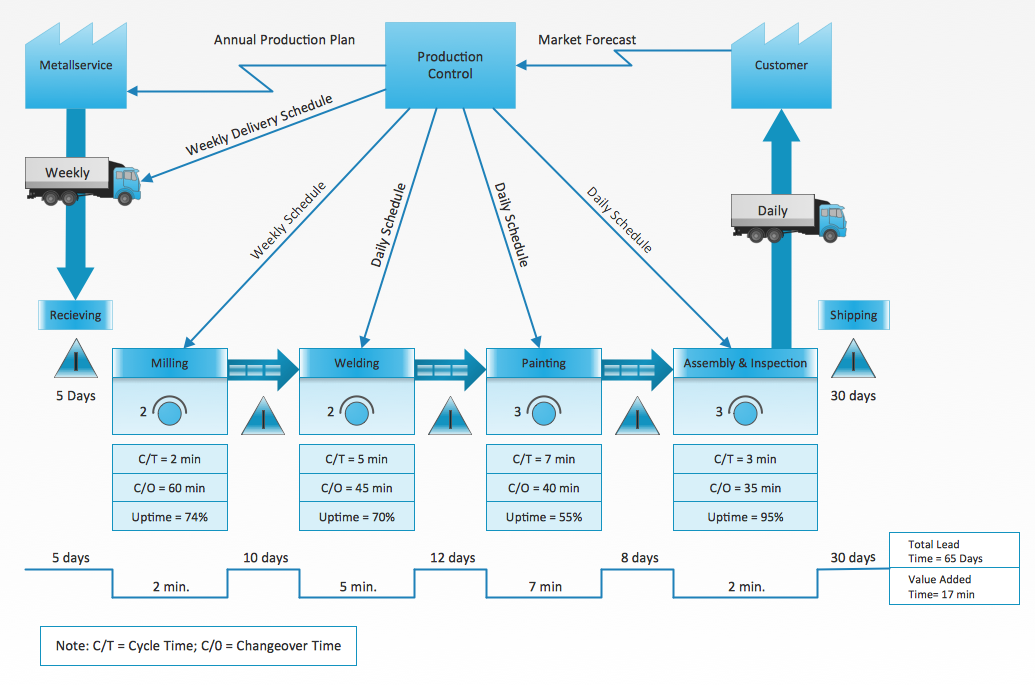

Value Stream Mapping Template Value stream mapping is a lean management method used to document the flow of information or materials required. Here is a free value stream map template created by Edraw. Using Edraw to experience the easiest way to capture, analyze, and share quality value streams. Work with custom Value Stream Maps via their VSM files and add, remove, modify, and reconfigure their content, specific components, material information, and other content. The 1.2.2.0 version of Value Stream Mapping is available as a free download on our website. Our built-in antivirus scanned this download and rated it as 100% safe. Value Stream Mapping Definition. Value Stream Mapping (VSM): – Special type of flow chart that uses symbols known as 'the language of Lean' to depict and improve the flow of inventory and 2 information. Create Value Stream Mapping online within seconds. No Download Needed. Start with a FREE account now!

Value stream mapping is a visual diagram that represents the activities to produce a product or service through the design, source, make, and deliver functions. Creating a value stream is the first step required in any lean improvement initiative.

One uses this tool to graphically represent the current state of a process. The graph includes icons to show the sequence of materials, processes, and information for the specific process.

The map shows two main components. The value stream illustruates the flow of materials through the transformation processes to produce the finished goods or services. The map also documents the flow of information to support the transformation process for the finished goods or services. If you leave off the information flow, you limited the benefit of the value map.

8D Manager Software with 8D, 9D, 5Y and 4M report generator. Your corrective action software for managing, measuring, and reporting issues.

8D Manager

With the map you can identify waste and then determine the process's future afte the elimination of the non value added steps. Combine the map with the lean principles and lean tools to truly transform the enterprise and achieve improvement. Think about the map's visible opportunities to drive out waste and the resulting significant positive impact on the financial performance for the enterprise and all stake-holders.

Free Value Stream Mapping Excel Template Software

It is not uncommon for a specific value stream to yield 5% value-added content to 95% non-value-added content.

Value Stream Mapping lets you...

- Create a graphic visualization of the entire material and information flow for the current-state value stream.

- Show linkages and connections between information flow and material flow.

- Identify sources of waste in the value stream.

- Provide common language for talking about the processes.

- Make decisions about the apparent flow.

- Form the basis of an implementation plan to identify and eliminate wastes.

- Identify non-value-added steps, lead time, distances traveled, and amount of inventory for a process.

- Provide a common language for discussing the future-state value stream and identifying gaps between the current state and future state.

An Example

An example of a process map for blood bank operations is shown below.

More Info

What is Continuous Improvement?

We answer the question, 'What is continuous improvement'. Quality Assurance Solutions provides the continuous improvement tools.

Here we Define Kaizen Events, Blitzes, and the 5S Concept.

We define Kaizen as an important continuous improvement tool for your business. Understand the Kaizen 5S concept of small improvement changes.

Benchmarking Definition and Benchmarking Best Practices

Our Article on benchmarking definition, benchmarking best practices, advantages of benchmarking and benchmarking steps. What is benchmarking?

Lean Manufacturing

Lean manufacturing is a generic process management philosophy derived mostly from the Toyota Production System (TPS)

7 Wastes of Lean

Learn the 7 Wastes of Lean with this article.

Lean Thinking

Become a friend with lean thinking.

Quick Changeover

a NARROW view of Quick changeover as only the time required to pull an existing tool or fixture and set the new tool or fixture

One Piece Flow

One piece flow and work cells that support this

Mistake proofing

Mistake proofing is defined as an improvement technology that uses a device or procedure

Level Mix Model Production

Level Mix Model Production means scheduling daily production in a sequence that evens out the peaks and valleys of produced quantities. Learn more!

Theory of Constraints Concepts and Details

See our article on Theory of Constraints. Every system keeps at least one constraint that limits the system outputs

Takt Time

Takt Time is defined as :The rate at which the end product or service must be produced

Spaghetti

Spaghetti Map or Physical Process Map is the simplest Lean Sigma tool. It demonstrates the physical flow of an entity or multiple entity types

SMED

SMED: Rapid changeover or rapid setup is also known asSingle Minute Exchange of Dies (SMED) and was devised by ShigeoShingo

OEE

Overall Equipment Effectiveness ( OEE ) is used extensively in the maintenance and equipment reliability world to examine equipment availability.

TPM

TPM Total Productive Maintenance: Logistics, OEE, Tools and roadmap

The 7 Wastes of Lean

Learn the 7 wastes of Lean, how they affect your company's bottom line and the actions to counter these wastes.

Quality Assurance Solutions

Robert Broughton

(805) 419-3344

USA